Our products bearing the Premium Quality and Sustainability label undergo a series of rigorous control processes both during and after production. This label signifies that the product has undergone thorough examination at various stages of manufacturing, ensuring adherence to stringent quality standards. Additionally, it indicates that the product is crafted from renewable materials, following environmentally friendly and energy efficient procedures.

Finished inspection

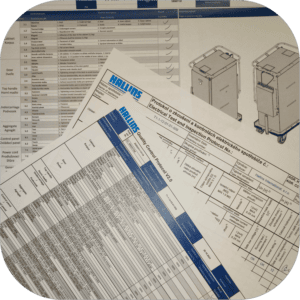

To enforce quality control throughout production, we establish checkpoints at key phases, guaranteeing precise product settings and compliance with quality levels. QR code-enabled labels are employed during this process to provide information about conducted inspections. During the final inspection, a detailed quality control protocol is generated for each product, outlining all measurements of functional values.

Quality QR labels

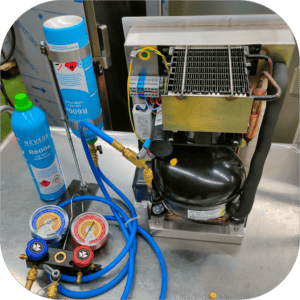

From inception, our products are designed and manufactured with a commitment to sustainability and the promotion of a circular economy. Materials used in their production are carefully chosen with consideration for recyclability and environmental friendliness. For instance, Temptainer Generation-4 cooling units now feature the environmentally friendly refrigerant. The goal of our innovative manufacturing processes is to reduce power consumption and waste, with the latter being directed towards recycling.

Refrigerant filling

Incorporating sustainable practices in the work environment not only benefits the planet but also enhances our employees’ well-being by fostering a healthier, eco-conscious workplace that contributes to a positive and fulfilling professional experience.

Inspections

The new label is intended to assure customers that their product meets the exacting standards set by Hallins. It serves as a testament to our dedication to delivering products of the highest quality while prioritizing sustainability in every aspect of our production.

Control protocols