European stainless steel instead of aluminum

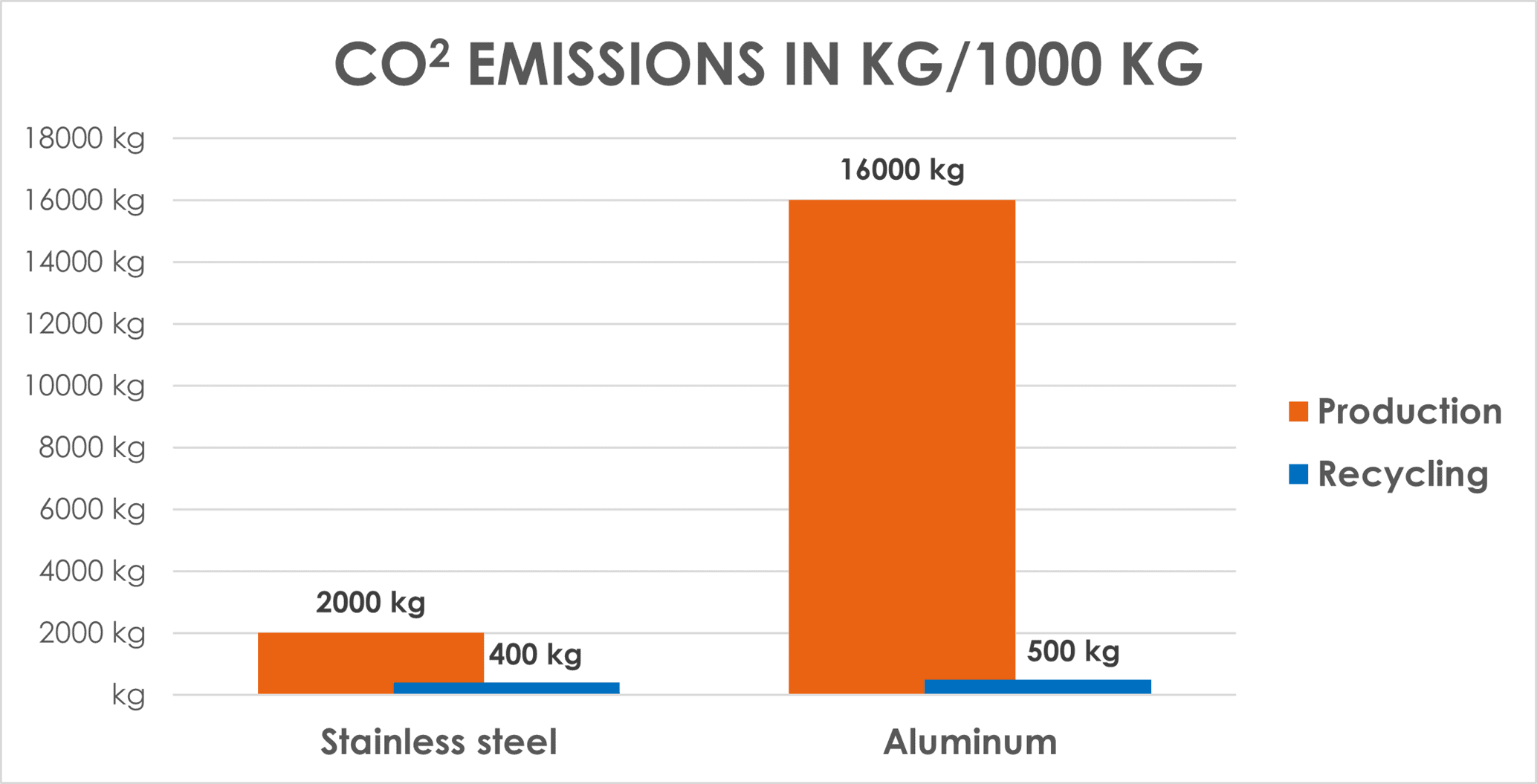

When producing 1,000 kg of stainless steel, approximately 2,000 kg of CO2 emissions are generated.

Recycling 1,000 kg of steel slightly reduces CO2 emissions, typically resulting in around 400 kg of CO2, which is a lower figure compared to primary production.

For aluminum, the situation is different. Producing 1,000 kg of primary aluminum can result in up to around 16,000 kg of CO2 emissions, significantly higher than steel. That means making a 1,000 kg of aluminum emits more carbon than burning 5,000 kg of oil. Aluminum from China and India uses electricity from coal power. The aluminum that results is extremely carbon intense, reaching up to 20,000 kg CO2/1,000 kg.

However, aluminum recycling can significantly decrease emissions to approximately 500 kg of CO2.

It’s important to note that these figures are rough estimates and can vary depending on the specific production process, energy sources used, and other factors.

If you want to know more about steel and aluminum carbon footprint:

https://www.carbonchain.com/blog/understand-your-steel-emissions

https://www.carbonchain.com/blog/understand-your-aluminum-emissions

Stainless steel stands as a paramount material in our manufacturing processes due to its myriad of beneficial attributes that significantly contribute to the quality and reliability of our end products. Several key reasons underscore our preference for stainless steel:

Corrosion Resistance: The inherent corrosion resistance of stainless steel ensures that our products remain resilient against environmental factors such as moisture, chemicals, and varying temperatures. This characteristic significantly extends the lifespan of our manufactured goods, reducing the need for premature replacements and associated costs.

Durability and Strength: Stainless steel’s remarkable durability and high tensile strength provide our products with the structural integrity required to withstand demanding operational conditions. This ensures that our offerings maintain their performance excellence over extended periods, enhancing customer satisfaction and loyalty.

Hygiene and Cleanliness: The non-porous surface of stainless steel prevents the accumulation of contaminants, making it particularly suitable for applications requiring stringent hygiene standards.

Aesthetic Appeal: Stainless steel’s sleek and polished appearance lends an air of sophistication to our products. Its reflective surface contributes to a visually pleasing aesthetic, which can be advantageous in markets where aesthetics plays a significant role in purchasing decisions.

Recyclability and Sustainability: The eco-friendly nature of stainless steel aligns with our commitment to sustainable business practices. Its recyclability reduces our environmental footprint and resonates with environmentally conscious customers.

In conclusion, our strategic utilization of stainless steel underscores our dedication to delivering products of the highest caliber, aligning with our mission to meet and exceed customer expectations. The material’s unique combination of corrosion resistance, durability, hygiene compliance, aesthetic appeal, sustainability, and versatility collectively contribute to the overall excellence of our offerings.

We are proud to uphold our commitment to sustainability by utilizing stainless steel, a highly recyclable material, in the manufacturing of our trolleys. This conscious choice not only aligns with our dedication to environmental responsibility but also actively contributes to the establishment of a circular economy. By opting for stainless steel, we play a crucial role in reducing the consumption of finite resources, ensuring a greener and more sustainable future.

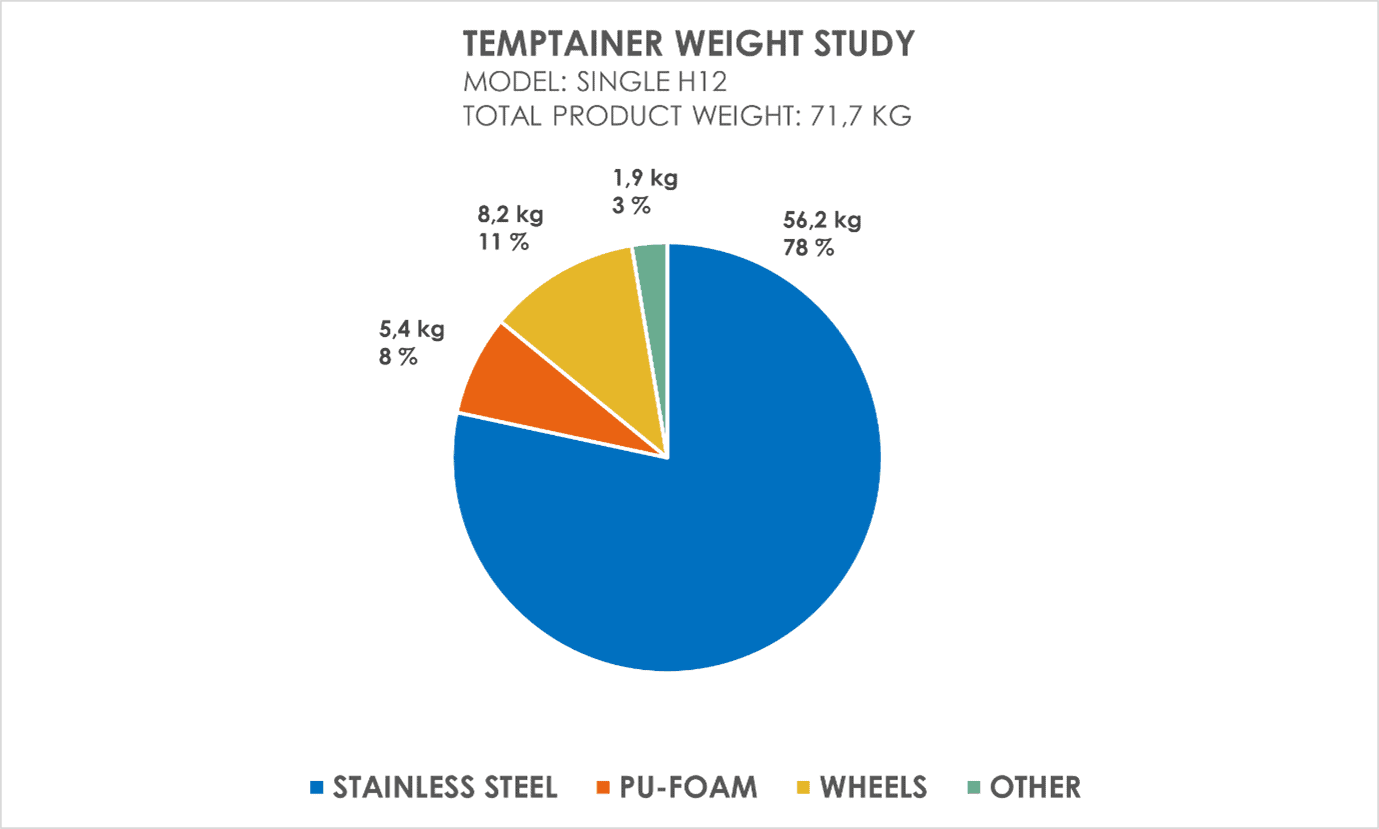

For a comprehensive overview of the sources of each component used in the construction of our trolleys, please refer to the provided total breakdown. At Hallins, we believe that sustainability and efficiency can go hand in hand, and our stainless steel trolley stands as a testament to this philosophy.