Upon the request of our Asian client, we were tasked with enhancing the capability to adjust internal air humidity effectively for trolleys equipped with active heating. Our design team met this challenge with agility, delivering a new add-on within a month. This innovation has been seamlessly integrated into Temptainer doors, meeting all customer specifications. The newly introduced accessory allows for precise manual regulation of water vapor generated during food heating, ensuring optimal humidity levels within the Temptainer.

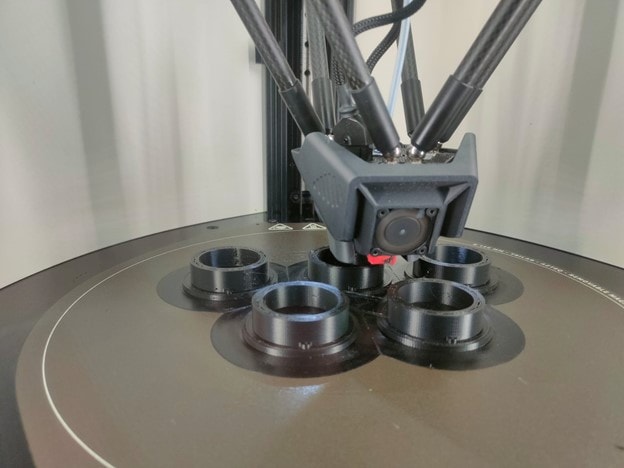

In the production of this new component, which comprises several precision parts, we opted for state-of-the-art 3D printing technology. Hallins International made a strategic investment in professional 3D printing equipment, leveraging its capabilities not only for component manufacturing but also to expedite the development, prototyping, and testing of new parts.

This strategic move not only facilitated the production of the new component but also streamlined our overall development process. Consequently, our customer received a precise solution to their request within an unprecedented timeframe, adhering to the highest quality standards.